Dry-Type Bushings in Power Grid Systems: Applications, Advantages, and Trends

1. Overview of Dry-Type Bushings in Power Grids

Transformer bushings are essential components that safely transfer current from inside the transformer to external circuits. Traditional

oil-immersed capacitive bushings (oil-paper bushings) suffer from sealing problems, moisture ingress, insulation aging, and overheating, contributing to a high failure rate.

In particular, 500 kV and above oil-paper bushings have shown frequent failures and have even caused transformer fires, posing major risks to power grid safety. To address these issues,

dry-type transformer bushings have become a safer alternative due to their fireproof, explosion-proof, maintenance-free, and high-mechanical-strength properties.

2. What Are Dry-Type Transformer Bushings?

Dry-type bushings use solid insulation materials, replacing oil-filled insulation. Common materials include:

Epoxy-Impregnated Paper (EIP) Dry-Type Bushings

- Based on advanced international technology.

- Relatively high cost and complex production process.

- Often used for converter transformers in HVDC applications.

Epoxy-Impregnated Fiber / FRP Dry-Type Bushings

- Lightweight and high mechanical strength.

- Stable insulation performance.

- Can achieve insulation levels up to 1200 kV UHV.

Due to excellent mechanical and insulation characteristics, epoxy-fiber dry bushings are suitable for a wide range of transformer environments.

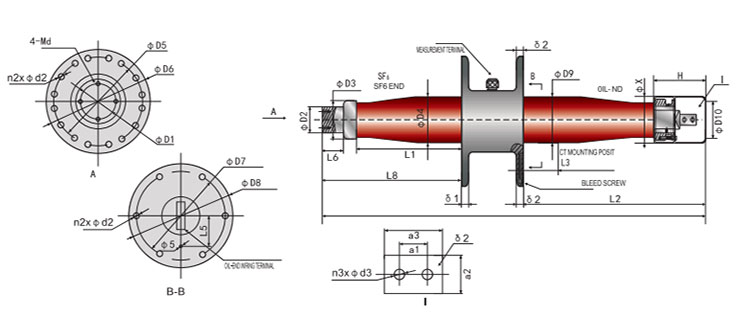

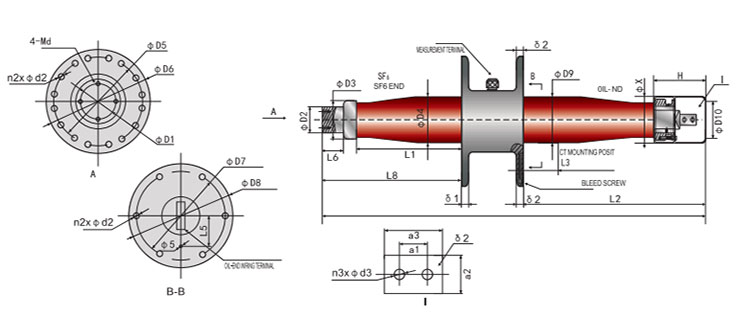

3. Types of Dry-Type Bushings

Dry-type bushings can be designed for multiple installation scenarios:

- Oil–Air Bushings (commonly used for power transformers)

- Oil–SF6 Bushings for GIS-connected transformers

- Oil–Oil Bushings between oil-filled equipment

- DC Converter Bushings for HVDC systems

- Wall Bushings for substation building penetrations

- GIS Outlet Bushings for compact substations

Many models support multi-angle installation and customized structural designs.

4. Key Advantages of Dry-Type Bushings

1. Fireproof and Explosion-Proof

Dry-type bushings contain no oil, eliminating risks of leakage, fire, or explosion. Many historical transformer fires originated from oil-paper bushing failures—an issue avoided entirely with dry-type designs.

2. Maintenance-Free Operation

No oil level checks, pressure monitoring, or oil sampling are required. Dry bushings are lighter, impact-resistant, and require minimal long-term maintenance.

3. High Mechanical Strength

Solid insulation cores and composite housings provide high structural integrity, suitable for harsh vibration environments and seismic regions.

4. Higher Insulation Margin

Dry-type bushings typically offer greater insulation thickness and higher safety margins—often exceeding 30% compared to oil-paper designs.

5. Strong Pollution Resistance

Hydrophobic silicone rubber sheds maintain superior performance in contaminated areas such as coastal or industrial zones.

Epoxy-Impregnated Paper Bushings

Some field cases reported moisture issues, sealing defects, and partial discharge anomalies.

Epoxy-Impregnated Fiber (FRP) Bushings

Only isolated batch-related issues have been noted; overall field reliability is excellent.

Performance by Voltage Level

- 110 / 220 kV: 10+ years of stable operation in many grids.

- 500 kV: Widely used since 2012 with proven performance.

- 1200 kV: FRP bushings already applied in UHV AC/DC systems.

Fire-Safety Verification

Importantly, no dry-type bushing failures have led to transformer fires, confirming the inherent safety of solid insulation systems.

6. Development Trends

Broader Application Scenarios

Dry bushings are increasingly used in:

- Urban distribution networks

- UHV and HVDC transmission

- Compact GIS substations

- Railway traction transformers

- Renewable energy systems

- Superconducting fault current limiters

Replacement Trend

Due to safety, environmental protection, and low maintenance, dry-type bushings are gradually replacing traditional oil-paper bushings worldwide.

Key Development Focus

Future development emphasizes improved design structure, defect prevention, consistency control, and long-term reliability to meet the strict requirements of modern power grids.

7. Conclusion

Dry-type transformer bushings represent a major advancement in power system reliability. With their fireproof, explosion-proof, maintenance-free, and high-insulation characteristics, they provide safer and more stable performance for high-voltage and ultra-high-voltage applications.

Their adoption supports safer and more efficient operation in modern grids, renewable energy systems, and urban distribution networks.